Views: 0 Author: Site Editor Publish Time: 2025-10-23 Origin: Site

Titanium dioxide (TiO₂) is a powerhouse in the coatings industry. It significantly enhances the durability of paints and coatings, especially by protecting against harmful UV radiation. This article explores how TiO₂ improves UV protection, its key benefits, and various applications across industries. You’ll learn how it works and its future in the coatings market.

Titanium dioxide (TiO₂) is an inorganic compound made from the metal titanium. It appears as a fine, white powder and is known for its high refractive index and excellent opacity. Due to these properties, TiO₂ is primarily used as a pigment in paints, coatings, and cosmetics. Its light-scattering ability makes it an ideal choice for enhancing the brightness and coverage of coatings.

Besides its use in coatings, titanium dioxide is employed in a range of other applications, including food products, sunscreen, and industrial manufacturing. In the context of coatings, TiO₂ is highly valued for its UV resistance, which helps to protect surfaces from the degradation caused by sunlight.

Titanium dioxide’s unique optical properties play a key role in its ability to provide UV protection. The material’s high refractive index allows it to scatter light effectively, creating an opaque layer on the surface of coatings. This scattering of light not only enhances the whiteness and brightness of the coating but also contributes to its ability to block UV radiation. TiO₂ absorbs and reflects UV rays, reducing the risk of surface degradation caused by prolonged exposure to sunlight.

In addition to its optical properties, titanium dioxide is chemically stable and non-reactive, making it resistant to photodegradation. This helps coatings maintain their performance and appearance even under intense sunlight.

Property | Description |

High Refractive Index | Scatters light effectively, enhancing opacity and brightness. |

Photochemical Stability | Resistant to degradation under UV exposure, maintaining coating integrity. |

UV Blocking Ability | Absorbs and reflects UV radiation, preventing damage to surfaces. |

Titanium dioxide’s UV protection mechanism is primarily based on its ability to absorb UV light and convert it into heat energy. The compound absorbs the harmful rays from the sun, preventing them from penetrating the coated surface. This UV-absorbing capacity helps to protect the material from fading, discoloration, and the breakdown of its structure over time.

In essence, TiO₂ acts as a barrier, reflecting and scattering UV radiation away from the coated surface. The result is that the coating stays vibrant, durable, and intact for much longer than it would without this protection.

Titanium dioxide’s high refractive index is one of the key properties that contribute to its effectiveness in UV protection. This property allows TiO₂ particles to scatter incoming light in various directions. The scattering of light helps to enhance the opacity of the coating and contributes to its ability to block UV rays. By reflecting UV radiation away from the surface, TiO₂ ensures that the material beneath is shielded from potential damage.

Titanium dioxide is known for its excellent photochemical stability. Unlike many other compounds, TiO₂ does not undergo significant degradation when exposed to UV radiation. This makes it ideal for use in outdoor coatings, which are constantly subjected to sunlight. The stability of TiO₂ under UV exposure ensures that the protective qualities of coatings remain intact over time, extending the lifespan of the material.

Recent innovations have focused on the use of nano-sized TiO₂ particles to enhance the UV protection offered by this compound. Nano-TiO₂ particles have a much higher surface area compared to their bulk counterparts, allowing them to scatter light more effectively. This results in superior UV protection with less material. Additionally, nano-TiO₂ particles can be more easily incorporated into coatings, improving their overall performance.

By using nano-TiO₂, manufacturers can create thinner, more efficient coatings that provide the same level of UV protection as traditional coatings, but with less material and potentially lower costs.

TiO₂ is widely used in exterior paints and coatings to protect buildings and structures from UV-induced fading and weathering. As an outdoor coating is constantly exposed to the sun’s rays, it requires a material that can absorb and reflect UV radiation, preventing degradation and preserving its aesthetic appeal. The incorporation of TiO₂ into these coatings ensures that the surface remains vibrant, even under harsh environmental conditions.

By providing long-lasting UV protection, titanium dioxide helps to extend the life of the coating, reducing the need for frequent repainting or repairs. This makes it an essential ingredient for exterior paints, especially in regions with high levels of UV radiation.

In the automotive industry, TiO₂ is a crucial component in automotive finishes, where UV protection is essential for maintaining the vehicle's appearance and integrity. The UV resistance provided by titanium dioxide helps to prevent paint from fading, cracking, or peeling, which can result from prolonged exposure to the sun. This is particularly important in regions with intense sunlight, where cars are more likely to experience UV-related damage.

In addition to protecting the exterior paint, TiO₂ also helps to preserve the gloss and shine of the finish, ensuring that vehicles maintain a like-new appearance for longer periods.

Titanium dioxide is also used in industrial coatings, where its UV protection properties are vital for enhancing the longevity of machinery, equipment, and infrastructure. Exposed to UV rays, these surfaces can suffer from fading, corrosion, and degradation over time. By incorporating TiO₂ into industrial coatings, manufacturers can improve the durability of these surfaces, ensuring that they remain functional and visually appealing for extended periods.

The UV resistance provided by TiO₂ is especially important for infrastructure such as bridges, pipelines, and other outdoor equipment that must withstand harsh environmental conditions.

Coating Type | Application | Benefit of Titanium Dioxide |

Exterior Paints | Used in paints for buildings | Protects surfaces from fading and weathering |

Automotive Coatings | Used in automotive finishes | Prevents paint fading and extends vehicle lifespan |

Industrial Coatings | Used on machinery and equipment | Enhances resistance to UV degradation and corrosion |

One of the primary benefits of incorporating TiO₂ into coatings is its ability to prevent fading and degradation. UV radiation is one of the leading causes of paint and coating deterioration, resulting in a loss of color and gloss. By blocking UV rays, titanium dioxide helps to maintain the vibrancy and appearance of the coating, even after prolonged exposure to sunlight.

This contributes to the long-term aesthetic appeal of the coated surface, whether it’s a building, vehicle, or industrial asset.

Titanium dioxide enhances the overall durability and longevity of coatings. The UV protection it provides helps to reduce the rate at which coatings break down, ensuring that the surface remains intact for longer. This is especially important for coatings applied to exterior surfaces, which are constantly exposed to environmental stressors such as UV radiation, moisture, and temperature fluctuations.

By improving the durability of coatings, TiO₂ reduces the need for frequent maintenance and repaints, saving time and money for businesses and property owners.

Coatings containing titanium dioxide help to reduce long-term maintenance costs by extending the intervals between repainting and repairs. The UV protection provided by TiO₂ ensures that surfaces retain their quality and appearance for longer, reducing the frequency of costly maintenance work. This is particularly beneficial for industries where maintenance costs can quickly add up, such as in construction, automotive, and industrial sectors.

Advantage | Explanation |

Improved Durability | TiO₂ increases the longevity of coatings by preventing UV damage. |

Reduced Maintenance Costs | Reduces the frequency of repainting and repairs due to superior UV protection. |

Enhanced Aesthetic Appeal | TiO₂ provides a bright, opaque finish that improves the overall appearance of coatings. |

Titanium dioxide is considered non-toxic and safe for use in coatings, making it suitable for a wide range of applications, from residential to commercial. Despite its safe usage, the production of TiO₂ can have environmental impacts, particularly regarding energy consumption and the release of certain chemicals during manufacturing. However, significant efforts are being made to reduce these environmental effects through more sustainable production methods.

With increasing demand for eco-friendly products, TiO₂ manufacturers are focusing on greener production processes, including the use of recycled materials and energy-efficient techniques.

The production of titanium dioxide can be energy-intensive, involving complex processes like the chloride or sulfate method to extract TiO₂ from titanium ore. These processes require large amounts of energy, contributing to the carbon footprint of TiO₂ production. However, ongoing research is exploring ways to make TiO₂ production more energy-efficient and environmentally friendly.

Manufacturers are exploring alternative methods for extracting TiO₂ that require less energy and generate fewer harmful byproducts, making the compound more sustainable in the long run.

Although titanium dioxide is chemically inert and does not pose significant environmental risks when used in coatings, its persistence in the environment can be a concern. TiO₂ is not biodegradable, meaning it can accumulate in ecosystems if not properly disposed of. Proper disposal and recycling methods are essential to prevent environmental contamination.

New research into biodegradable alternatives is underway, and regulations are in place to ensure the responsible use and disposal of TiO₂.

Nanotechnology is revolutionizing the use of titanium dioxide in coatings. Nano-TiO₂ particles offer enhanced light scattering and UV protection, providing more efficient and durable coatings. These particles can be dispersed more evenly, leading to smoother finishes and better performance.

Nano-sized TiO₂ particles are also used to develop coatings with additional functionalities, such as self-cleaning properties, antimicrobial effects, and energy-efficient coatings.

The push for sustainable materials is driving innovation in the TiO₂ industry. Researchers are exploring greener methods for producing TiO₂, focusing on reducing the environmental footprint of the compound. Green sourcing practices, such as using renewable energy and recycled materials, are becoming more common.

These sustainable approaches will not only improve the environmental impact of TiO₂ but also meet the growing demand for eco-friendly coatings in industries worldwide.

The demand for UV-resistant coatings is expected to grow in the coming years, driven by the increasing need for durable and long-lasting coatings in sectors like construction, automotive, and packaging. Titanium dioxide will continue to play a central role in these advancements, ensuring that coatings maintain their quality and functionality over time.

With rising concerns over climate change and environmental protection, the demand for coatings that offer both UV resistance and sustainability will continue to shape the market for TiO₂.

Titanium dioxide plays a vital role in improving UV protection in coatings. Its unique properties, like high refractive index and photochemical stability, make it indispensable for various applications, from exterior paints to automotive and industrial coatings. By protecting surfaces from UV radiation, TiO₂ extends their lifespan and reduces maintenance costs. As demand for eco-friendly coatings grows, innovations in nanotechnology and sustainable production methods will keep TiO₂ at the forefront. Companies like Huilong Baichuan offer TiO₂ products that deliver superior performance, meeting both industry standards and environmental goals.

A: Titanium Dioxide acts as a barrier by scattering and reflecting UV light, preventing the degradation of surfaces like paint and coatings.

A: Titanium Dioxide is favored for its high refractive index, photochemical stability, and ability to block UV radiation, improving coating durability.

A: Titanium Dioxide enhances the opacity, brightness, and longevity of coatings, providing strong UV protection and reducing maintenance costs.

A: Yes, Titanium Dioxide helps maintain color vibrancy and prevents fading by blocking harmful UV rays that would otherwise degrade the coating.

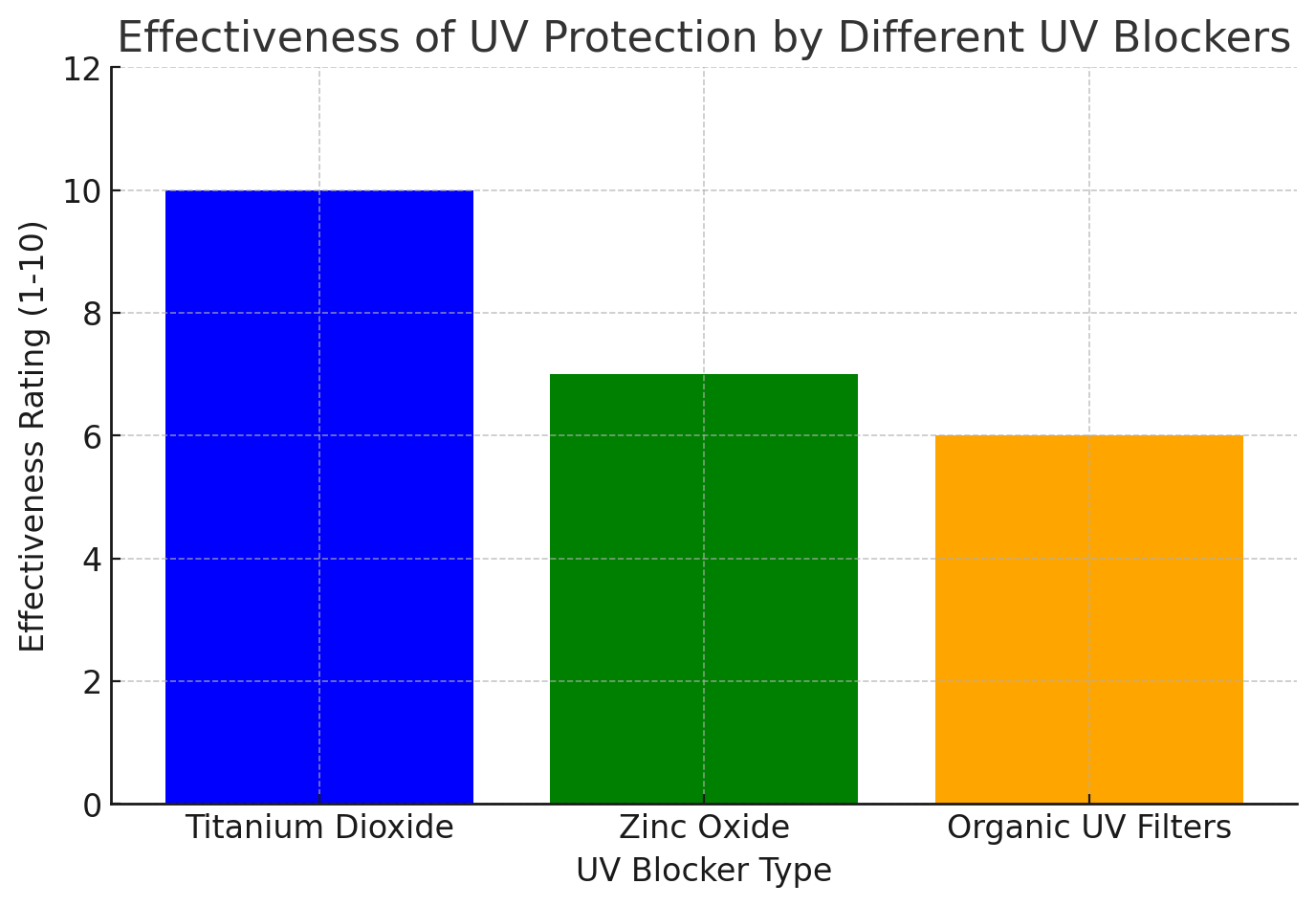

A: Titanium Dioxide outperforms many UV blockers due to its high opacity, stability, and ability to provide long-lasting UV protection in coatings.